أرسل لنا رسالة

roller crusher known

Roll Crushers - Top 2022 Models - 911 Metallurgist

Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth

Roll crusher, also known as roller crusher, belongs to traditional crushing equipment. It is mainly used for fine processing of material particles. As the main working part, the two cylindrical rollers rotate oppositely to achieve

Types of Crushers: What You Need to Know - Machinery Partner

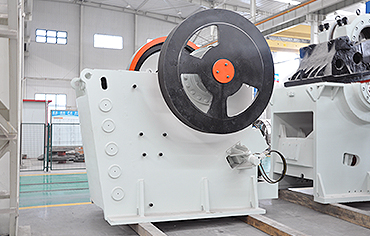

Eli Whitney Blake invented, patented, and sold the first actual rock crusher in 1858, it was known as the Blake Jaw Crusher. Blake’s crusher was so influential that today’s models are still compared to his original designs. ... Roller crushers. A roller crusher reduces material by compressing it between two turning cylinders, parallel to ...

McLanahan Roll Crushers

Single Roll Crushers. Single Roll Crushers are typically used as primary crushers that provide a crushing ratio of up to 6:1. They crush materials such as ROM coal, mine refuse, shale, slate, gypsum, bauxite, salt, soft shale, etc., while producing minimal fines.Designed with intermeshing roll teeth and a curved crushing plate, they are extremely effective in

Grain Mill Stops Pulling Grain Through - Homebrew Talk

2016年3月16日 If so I suggest you do search here on "worn roller barley crusher" or just search "grain mill worn roller" and you'll find the threads are all related to the barley crusher... Your problem is a very common issue with the Barley crusher mills. You can send the mill back to take the roller replaced and it should only cost you shipping and

Crusher - Wikipedia

Crusher. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of different ...

Roller crusher Gold Refining Metal Extraction Forum

2020年12月22日 Im thinking a set of rollers below my jaw crusher would work great. My question is, what is the typical, or ideal, ratio of material size feeding a roller crusher? ... Thanks . Reply. G. goldshark Well-known member Supporting Member. Joined Aug 12, 2021 Messages 1,042. Jan 23, 2022 #2 The typical throughput on every modern crusher

Double Roller Crusher - JXSC Machine

The Doule Roller Crusher, also known as roll crushe r, or toothed roll crusher, is suitable for fine crushing medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, and chemical materials. According to the number of rolls, the roll crushers can be ...

EWAC Alloys Limited

Open arc self-shield continuous wire for build-up of table and roller liners. Applications: Coal mill crusher hammers; Table liners; Rolls and roller liners in cement plants as well as thermal power stations

EP2911793B1 - Eccentric roller crusher - Google Patents

2023年6月14日 The well-known eccentric roller crusher is characterized by low losses, low wear and relatively compact dimensions. Der Brechspalt wird zwischen der Walze und der zumindest einen Schwinge gebildet. Unter Berücksichtigung der exzentrischen Hin- und Herbewegung der Walze ergibt sich ein äußerer Berührungskreis der Walze, der von dem

Long-lasting roller crusher and sizer solutions I

Robust roller crusher and sizer offering to maximise your crushing capabilities. Our roller crushers and sizers are built to last, with strong frames and self-lubrication systems to reduce your maintenance burdens. They offer reliable crushing of materials in the cement and mining industry, including highly-abrasive and sticky ones, and ...

High pressure grinding rolls HRC 8 HRC - Metso

rollers RPM and other key parameters in your crusher. The protection is activated in steps, starting from informative warnings, then progressing to inform and log data for operational improvement, troubleshooting, and eventually shutting down the crusher to protect it whenever needed. Consistent performance

Heavy-duty Roll Breaker -

Low maintenance by design. The Heavy-duty Roll Breaker is designed to operate at lower speed that does not have the same wear impact as a Hammer crusher. The crushing segments has a wear lifetime of at least 3 years and have been known to last more than 5 years, thereby a low maintenance.

BR112015009402B1 - Eccentric Roll Crusher - Google Patents

2012年10月29日 The known eccentric roller crusher is characterized by low losses, low wear and relatively compact dimensions. [004] A abertura de britagem é formada entre o rolo e pelo menos um braço oscilante. Devido ao movimento de vaivém do rolo é gerado um círculo de contato externo do rolo, que é percorrido pelo revestimento do rolo no caso de

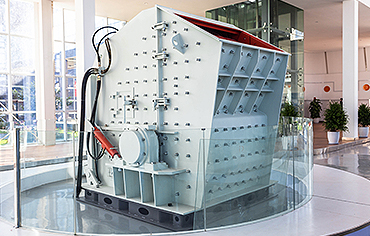

Size Reduction – Visual Encyclopedia of Chemical Engineering

General Information/Equipment Design. Size reduction in impact crushers occurs through particle concussion by rigid forces. The hammer crusher, also called the hammer mill, is an example of an impact crusher. In hammer crushers, hammers swing freely on a disc mounted on the main shaft within the device.

Crushing Equipment Market Size to Grow by USD 342.32 million,

2022年7月19日 They are also known as universal crushers, as they can be used in various sectors, such as quarrying, heavy mining, and recycling. ... 5.4 Roller crushers - Market size and forecast 2020-2025 ...

Heavy-duty Roll Breaker -

Low maintenance by design. The Heavy-duty Roll Breaker is designed to operate at lower speed that does not have the same wear impact as a Hammer crusher. The crushing segments has a wear lifetime of at least 3 years and have been known to last more than 5 years, thereby a low maintenance.

BR112015009402B1 - Eccentric Roll Crusher - Google Patents

2012年10月29日 The known eccentric roller crusher is characterized by low losses, low wear and relatively compact dimensions. [004] A abertura de britagem é formada entre o rolo e pelo menos um braço oscilante. Devido ao movimento de vaivém do rolo é gerado um círculo de contato externo do rolo, que é percorrido pelo revestimento do rolo no caso de

Size Reduction – Visual Encyclopedia of Chemical

General Information/Equipment Design. Size reduction in impact crushers occurs through particle concussion by rigid forces. The hammer crusher, also called the hammer mill, is an example of an impact crusher. In

Crushing Equipment Market Size to Grow by USD 342.32 million,

2022年7月19日 They are also known as universal crushers, as they can be used in various sectors, such as quarrying, heavy mining, and recycling. ... 5.4 Roller crushers - Market size and forecast 2020-2025 ...

Screening Machine Company Sieving Machine Manufacturer

2017年4月27日 With the registered capital of RMB 25 million Yuan and more than 300 employees, Gaofu company covers an area of 60000 square meters and a building area of 32,000 square meters. Gaofu shares were listed on the New OTC on March 25, 2016 (stock code: 836946). In 2017, the company’s brand "GAOFU ®" was identified as "China Well

EP2911793A1 - Eccentric roller crusher - Google Patents

The well-known eccentric roller crusher is characterized by low losses, low wear and relatively compact dimensions. Der Brechspait wird zwischen der Walze und der zumindest einen Schwinge gebildet. Unter Berücksichtigung der exzentrischen Hin- und Herbewegung der Walze ergibt sich ein äußerer Berührungskreis der Walze, der von dem Mantel ...

EP2911792A1 - Roller crusher - Google Patents

Eccentric roller crushers are also known from DE 1 140 799, DE 2 733 379 A1, DE 1 889 686, DE 1 257004 and DE 1 875 346. Die erfindungsgemäße Abstützung der Absiebeeinrichtung an der Brecherwabe ist jedoch auch bei Walzenbrechern möglich, deren Brechwalze keine Hin- und Herbewegung vollzieht. Im Rahmen einer solchen alternativen

Top 10 Crusher Machine Working Principle [GIF Picture] MC

7. Roller Crusher. Roller crusher, also known as double roller crusher, when the material enters between two rollers, due to the effect of friction, the ore is carried into the crushing space between the two rollers, compressed and crushed. The roller crusher has a simple structure, occupies small space, and is easy to operate and maintain.

Types of crushing machines - Simple English Wikipedia, the free ...

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. [1] There are four traditional types of crushers in materials engineering. They are known as jaw crushers, gyratory crushers, cone crushers and roll crushers.

Double-Roller Crushers For Sale - FTM Machinery

2019年8月13日 The precautions of roller crushers should be known. 1.Strengthen the work of iron removal. Dropping the non-crushed material into the rolls can damage the double-roller crushers thus causing the stopping. Therefore, a de-ironing device should be installed in front of the crusher.

Roll Crushers - ScienceDirect

2016年1月1日 Heavy duty toothed rollers are sometimes used as primary crushers, but the use of such rollers in the metallurgical industry is very limited. Download : Download full-size image; Figure 6.1. Schematic Diagram of Roll Crushers. ... For a particular operation where the ore size is known, it is necessary to estimate the diameter of rolls required ...

DE102012110331A1 - Eccentric roller crusher - Google Patents

The well-known eccentric roller crusher is characterized by low losses, low wear and relatively compact dimensions. Der Brechspalt wird zwischen der Walze und der zumindest einen Schwinge gebildet. Unter Berücksichtigung der exzentrischen Hin- und Herbewegung der Walze ergibt sich ein äußerer Berührungskreis der Walze, der von dem Mantel ...

Roller Crusher Single/Double Roll Crushers - JSXC Mine

The crusher machine uses two opposite rotating rollers to crush the material. It is composed of an electric motor, support, a fixed roller, a movable roller, a safety spring, etc. With smooth and serrated surfaces. The bearings of the active rollers can move along the frame which supported by strong safety springs.

CN104768647A - Eccentric roller crusher - Google Patents

The invention relates to an eccentric roller crusher comprising a crusher housing (1), a drive shaft (2), a roller (3) which is eccentrically and rotatably mounted on the input shaft, and a rocker (4) which can be pivoted about an axis of oscillation (S) for adjusting an outlet gap (A) between the roller (3) and the rocker (4). According to the invention, an inlet gap