أرسل لنا رسالة

industrial sand crushing sizing

Evaluation of the crushing characteristics of industrial waste

2023年11月3日 For a particular stress level, crushing potential of larger size particles is more. Stress level and minerology are the dominant factors that decide particle breakage. Breakage index of industrial waste aggregates can be predicted from empirical models.

获取价格

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS

Maximum crushing efficiency, when using Bi-Flow® in a given crusher range, can be realized when the following parameters have been selected: • Maximum motor size for

获取价格

11.19.1 Sand And Gravel Processing - US EPA

Figure 11.19.1-2 is a flow diagram for industrial sand and gravel processing. The mined rock is transported to the processing site and stockpiled. The material then is crushed.

获取价格

Guide to the Proper Selection and Sizing of Industrial Crushers

Guide to the Proper Selection and Sizing of Industrial Crushers. Crushers are machines that use impact, shear, compression or abrasion to reduce a variety of solid products to a

获取价格

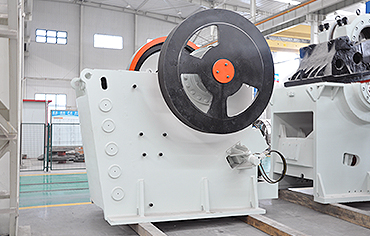

McLanahan Jaw Crushers

Still using the 32 x 54 Jaw Crusher example, the top size of the feed entering the crushing chamber has to follow the F80 rule that 80% of the top size feed material is smaller than the gape opening. Using the F80 rule with the 32 x 54 Jaw Crusher, the 32” gape opening equals a 26” top sized feed, and with the 6:1 ratio of reduction, the ...

获取价格

Rock Crushers Pulverizers Williams Crusher

Contact us today to discuss your rock crushing application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. With industry

获取价格

11.19.1 Sand And Gravel Processing - U.S. Environmental

3-05-025, and the six-digit SCC for industrial sand and gravel is 3-05-027. Construction Sand And Gravel - ... or it may be directed to a crusher for size reduction, to produce crushed aggregate, or to produce manufactured sands. Crushing generally is carried out in one or two stages, although three-stage crushing may also be performed ...

获取价格

6 Sand Making Machines and How to Choose the Best One

2023年5月12日 Output size: 2-20mm. Price range: $14,400/ Set (the lowest price) Advantages. Under the same conditions, its output can be about 10% higher than that of an HVI sand machine. The fineness modulus is adjustable and

获取价格

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS

Maximum crushing efficiency, when using Bi-Flow® in a given crusher range, can be realized when the following parameters have been selected: • Maximum motor size for the relevant crusher size. • Tip speed selected at 0.9-1Kw / Tonne rotor throughput. • Crusher operated at maximum motor amps. with rotor only feed.

获取价格

McLanahan Screening/Sizing

Screening/Sizing. Sizing is the general separation of products according to their size. The simplest form of sizing is screening, the purpose of which is to separate minerals or other materials into specific particle sizes to create various final products. When selecting equipment to screen a product, considerations should be given to material ...

获取价格

Manufactured Sand Agg-Net

2008年6月2日 The resulting system is known as the V7 sand manufacturing plant (see fig. 1). Manufactured sand. Material described as manufactured sand can range from unprocessed quarry dust to, at best, carefully processed fine aggregate specifically designed for use in concrete or other products. It can be gritty, flaky, and full of filler 1, or it can be ...

获取价格

Crusher - Wikipedia

Crusher. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of different ...

获取价格

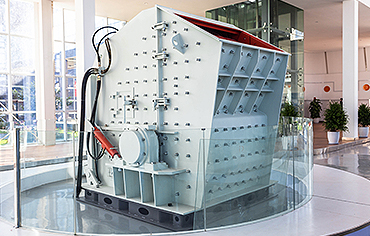

Impact Crusher Machines Williams Patent Crusher

Call (314) 621-3348, email us at info@williamscrusher or locate an agent near you. Impact crusher machines from Williams Crusher have a wide range of industrial applications from crushing rock to de-lumping sand.

获取价格

Choosing the Right Screening Equipment - Kemper Equipment

Depending on your specific aggregate processing application, screening equipment may fit in different points of your material handling operation. Screens size and separate your material after crushing, but they may be integrated just after the primary crusher—as in most crushed stone plants—or screening may occur just before stockpiling or material

获取价格

McLanahan Rotary Scrubbers

Rotary Scrubbers. Rotary Scrubbers are used to wash crushed rock, ore, sand, gravel, construction aggregates and oil sands. They are high-capacity, high-retention machines that can accept large-sized feed material and are used primarily to remove water-soluble clays, deleterious materials and coatings providing a cleaner product

获取价格

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

获取价格

Types of Sand: Uses, Properties, Grain size Classification.

1 Based on the grain size of the particle, sand is classified as Fine Sand(0.075 to 0.425mm), Medium Sand(0.425 to 2mm), and Coarse Sand(2.0 mm to 4.75mm) ... Manufactured Sand: Created by crushing hard granite stones, manufactured sand refers to an artificially created type of sand made as an alternative to river sand for construction.

获取价格

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that

获取价格

McLanahan Rotary Scrubbers

Rotary Scrubbers. Rotary Scrubbers are used to wash crushed rock, ore, sand, gravel, construction aggregates and oil sands. They are high-capacity, high-retention machines that can accept large-sized feed

获取价格

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

获取价格

Types of Sand: Uses, Properties, Grain size

1 Based on the grain size of the particle, sand is classified as Fine Sand(0.075 to 0.425mm), Medium Sand(0.425 to 2mm), and Coarse Sand(2.0 mm to 4.75mm) ... Manufactured Sand: Created by crushing

获取价格

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that

获取价格

Mechanical screening - Wikipedia

Mechanical screening. Mechanical screening, often just called screening, is the practice of taking granulated or crushed ore material and separating it into multiple grades by particle size . This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling.

获取价格

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

sized. The sand is then carried by a screw, which separates the sand from the water, to a conveyor belt, which carries it to a storage area. Water that is used in the plant is pumped from a freshwater pond. The discharged water is then pumped into a settling pond. A crushed stone plant differs somewhat from a sand and gravel plant. Raw material is

获取价格

Crushing Products Size and Shape -What to Expect - 911

2016年2月26日 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or 42% of the primary crusher product. If our problem had covered a crushing condition calling for 80 instead of 85% passing the

获取价格

7 Types of Sand Used in Construction - BuilderSpace

2020年1月6日 5. Industrial Sand. Industrial sand is a name that refers to high purity silica sand with controlled sizing. This sand type is widely used in building and construction projects. Whole grain silica is usually added to specialty cement, roofing shingles, flooring compounds, asphalt mixtures, and skid-resistant surfaces.

获取价格

Pugmills - Astec

Construction aggregate is typically medium or coarse materials like granite, limestone or trap rock, sand, gravel, slag or recycled concrete. Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles.

获取价格

Crushers Selection Guide: Types, Features, Applications - GlobalSpec

Primary crushing operations takes boulder size feeds (20 to 100 inches) and reduces the material to secondary crusher feed size (1 to 20 inches) or mill feed size (0.5 to 3 inches). ... Sand gravel. Gyratory crushers. Soft to very hard. Abrasive. Dry to slightly wet, not sticky ... Important specifications and features when selecting ...

获取价格

Choosing the right crusher - Buying Guides DirectIndustry

Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks ...

获取价格

Vertical Shaft Impactors - VSI Crushers - Stedman Machine

V-Slam™ VSI Models from Stedman are vertical shaft impactors for all your coarse-to-fine crushing needs. VSI crushers offer significant savings over higher-priced competitive crushers. The V-Slam, with its low horsepower per ton of throughput, minimizes operating costs. Our vertical shaft impactors feature multiple rotor configurations for ...

获取价格

Everything You Need to Know About Sand Making Machine

2021年9月29日 Manufactured sand:rock, mine tailings or industrial waste slag particles with particle size less than 4.7MM, which are made by mechanical crushing and screening after soil removal treatment, but soft and weathered particles are not included. ... Whether used for crushing or sand making, double roller sand making machine is very popular

获取价格

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material. During the primary crushing operation, boulder size feeds from 20 to 100 in. are reduced to secondary crusher sizes of 1 to 20 in. or mill feed size of .5 to 3 in.

获取价格