أرسل لنا رسالة

crusher design ceramic crusher

RETSCH instruments for ceramic production - McCrone

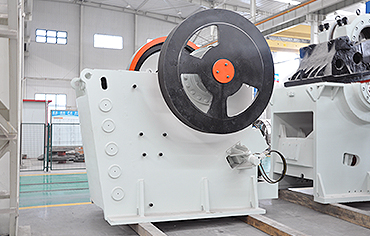

The jaw crushers are used for rapid, powerful crushing and pre-crushing of medium-hard, hard, brittle and tough materials which are typical for the ceramic industry. The

获取价格

进一步探索

Retsch - operating manuals - operating instructionsBrochures Flyers for Download - RETSCHJaw Crusher PDF Download - YUMPUKINEMATIC DIAGRAM OF THE JAW CRUSHER [16] - Crusher Product Gradation Charts - Mineral Processing

SELECTION OF CRUSHER DESIGN CONCEPTS AS A

conducted on previous researchers' three crusher design concepts: mo tor-operated crusher, mechanical crusher, and pneumatic crusher. This study shows that the

获取价格

进一步探索

(PDF) DESIGN OF MECHANICAL CRUSHING MACHINE - (PDF) Design and Development of Plastic Crusher for a More

Design of a crushing system that improves the crushing

The current system is slow and failing to keep up with their increased production rate. This paper proposes the design of a better crushing system at the mine will improve the

获取价格

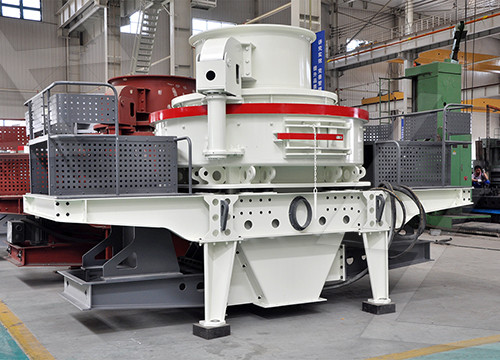

DEM-based design of feed chute to improve performance of cone

2021年7月1日 A DEM modelling approach was applied to improve the performance of a cone crusher by modifying design of feed chute. In order to simulate the overall crushing

获取价格

DEM-based design of feed chute to improve performance of cone crushers ...

2021年7月1日 The effect of feed chute design on tertiary cone crusher performance at the Sarcheshmeh copper complex was studied by an in-house developed DEM software called KMPC DEM ©. To simulate the overall crushing circuit, the multi-geometry procedure by improving the routines of object files importing into the simulation environment was

获取价格

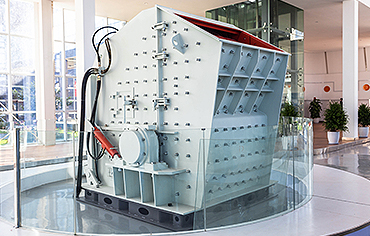

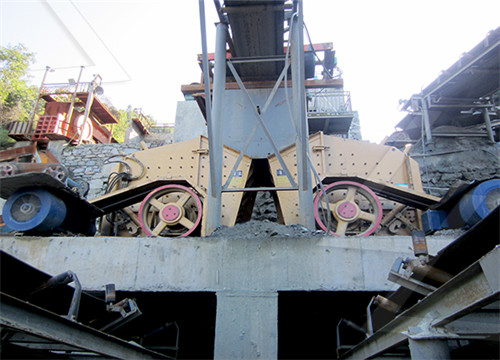

Hammer Crusher - Hammer Mill Machine AGICO Hammer Mill

A Hammer crusher (hammer mill machine) is a kind of equipment for crushing materials into smaller pieces by the repeated blows of little hammers. It is suitable for crushing the material with medium hardness and brittleness, the compressive strength is no more than 150 mpa and humidity is no more than 15%, widely used in cement plant, chemical ...

获取价格

Crusher - Wikipedia

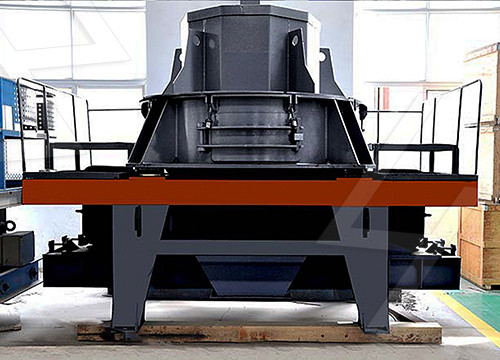

Crusher. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of different ...

获取价格

Types of Crushers - 911 Metallurgist

2015年6月23日 The design scheme of crushers: 1 – fixed cheek with the rotation axis; 2 – a movable cheek; 3, 4 – the eccentric shaft; 5 – rod; 6 – hinged rear bearing spacer cheeks; 7 – spring; 8, 9 – width adjustment mechanism of the discharge gap; 10 – pull the lock device; 11 – bed; 12 – still cone; 13 – cone moving; 14 – traverse ...

获取价格

Maximizing Your Crusher Blow Bars Lifespan - qimingcasting

Martensitic ceramic blow bars are white iron, ceramic, and martensitic steel. Maternistis is carbon-dense iron and has high resistance properties. When combined with high-graded ceramics, martensitic ceramic reduces the risk of damage, increasing blow bars’ longevity by 60%. Martensitic ceramic blowbars are best for recycling purposes.

获取价格

Roll Crushers - Lancaster Products

Lancaster Model 48 x 32 Double Roll Crusher. Roll opening: 12″ x 18″. Roll opening: 48″ x 32″. Each roll opening: 24″ x 32“. Drive: 5 HP. Drive: 30 HP. Capacity: Up to 3 ton/hour. Capacity: Up to 60 tons/hour. Lancaster Products Roll Crushers reduce – in a single pass- material previously requiring primary and secondary crushing.

获取价格

Jaw Crusher Explained - saVRee

Size Reduction) A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral(s) from the waste (gangue) material.Waste material can be discarded or recycled

获取价格

HAMMER CRUSHER HDS -

FORMER PRODUCT LINE. Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, Bituminous and Lignite. Crushing of the feed material is achieved by percussion, impact and shear forces.

获取价格

Hammer crusher - INFINITY FOR CEMENT EQUIPMENT

The design is a single rotor Φ800 × 900 mm, irreversible multi-row hinged hammer hammer crusher. It is suitable for crushing limestone, coal and gypsum or other medium hardness ore, crushing the material surface is not more than 8% moisture. This machine is gearing rotor, grate, and a framework of several parts.

获取价格

Primary Crusher Selection Design - 911 Metallurgist

2015年12月23日 A crusher’s wear parts need to last as long as operationally-economically possible. Typical numbers are for liner and mantles to have a useful wear-life of almost 2,000,000 tonne on abrasive taconite and 9,000,000 tonnes on porphyry copper ores. Dependability and long service life are landmarks of good primary crusher design of up

获取价格

Impact Crusher Parts Wear Parts For Industry Qiming Casting

Impact crushers are commonly used in the construction industry to process various materials such as gravel, limestone, and concrete. An impact crusher comprises a rotor, impact bars, and wear plates. The rotor is the main component of the crusher, and it rotates at high speed to generate the necessary impact force.

获取价格

RETSCH instruments for ceramic production - McCrone

the use of a jaw crusher equipped with a front door is recommended (e. g. BB 250, Fig. 1, BB 400) which allows easy access for cleaning. Fig. 2: Ceramic cones before and after size reduction in a jaw crusher Table 1: Pre-crushing of raw materials and intermediate products in jaw crushers retsch Application 2 APPLICATION

获取价格

Hammer Crushers -

Our Hammer Crushers. offers a double rotor Hammer Crusher and is used as primary crusher in cement industry for soft to medium-hard rock. They offer a very high crushing ration of 10:1 up to 80:1. The product is ideal as feed material to downstream ball mills or vertical roller mills. Double rotor Hammer Crushers are able to process ...

获取价格

Roll Crushers Williams Crusher

Contact us today to discuss your primary crusher application with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. Contact Us. Williams Crusher designs and manufactures a variety of Roll Crushers that provide efficiency and durability.

获取价格

Impact Crusher Parts Wear Parts For Industry

Impact crushers are commonly used in the construction industry to process various materials such as gravel, limestone, and concrete. An impact crusher comprises a rotor, impact bars, and wear plates. The rotor is the

获取价格

RETSCH instruments for ceramic production - McCrone

the use of a jaw crusher equipped with a front door is recommended (e. g. BB 250, Fig. 1, BB 400) which allows easy access for cleaning. Fig. 2: Ceramic cones before and after size reduction in a jaw crusher Table 1: Pre-crushing of raw materials and intermediate products in jaw crushers retsch Application 2 APPLICATION

获取价格

Hammer Crushers -

Our Hammer Crushers. offers a double rotor Hammer Crusher and is used as primary crusher in cement industry for soft to medium-hard rock. They offer a very high crushing ration of 10:1 up to 80:1. The product is ideal as feed material to downstream ball mills or vertical roller mills. Double rotor Hammer Crushers are able to process ...

获取价格

Roll Crushers Williams Crusher

Contact us today to discuss your primary crusher application with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. Contact Us. Williams Crusher designs and manufactures a variety of Roll Crushers that provide efficiency and durability.

获取价格

Clay Grinding Crushing Machine - Williams Crusher

Our Traveling Breaker Plate Mills can be used as a clay crushing machine. The mill is designed to permit a slugger crusher to reduce muddy rock and clay to ¾” or smaller. Its breaker plates continually “travel” while in use with all slack on the away side. This design lengthens the life of the plates and eliminates clogging when refining ...

获取价格

Hammer Crusher Working Principle - AGICO Cement Plant

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a

获取价格

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

获取价格

Lump Breaker-Dual Rotor Crusher Stedman Machine Company

Take your lumps – and get rid of them. Lump crusher design series includes the Aurora™ dual-rotor, Aurora Single Rotor, and the chain mill. Stedman's lump breaker machines are efficient and effective in size reduction for many products in various applications. ... Ceramic Brick Clay Crushers. Stedman revolutionized material preparation ...

获取价格

selection and purchasing guide of hammer crusher

The double rotor crusher has separate drive motors for each shaft. The weight of the replacable impact hammers is in the range of 20 to 200 kg each, depending upon the crusher size. The chemical composition of the hammer steel is: c = 1.0- 1.4 %. Si = 0.4- 1.0 %. Mn = 12.0-14.0 %. p = 0.06%.

获取价格

(PDF) Influence of jaw crusher parameters on the quality of

2020年3月19日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the ...

获取价格

Crusher, Crushing plant - All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h - 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a maximum crushing capacity of

获取价格

Crusher Wear Parts Foundry

Welcome to DENP. Founded in 2010, a global manufacturer and supplier of crusher wear parts and spare parts. DENP Foundry takes up 15000 square meters, and produce capacity of around 9000 tons annually, 84 workers and 7 engineers. So if you are looking for crusher wear parts and spare parts. DENP Industrial deserves your attention! VISIT FACTORY.

获取价格

Hammer Crusher Machine - Big Crushing Ratio And High Efficiency

Our hammer crusher machine can save the energy more than 50% than the same type of products. This can reduce your running cost. The use of wear-resistant material can reduce the wear of the lining plate and increase the service time. The body of hammer for crusheradopts sealing structure, which well solves the problem of dust pollution and dust ...

获取价格

5 Types of Concrete Crushers for Recycling Concrete Blocks

2023年2月28日 To recycle concrete, a crushing process is required. There are mainly 5 types of concrete crushers like portable crusher, mobile crusher, small concrete crusher, excavator concrete crusher and bucket crusher, so you have to choose the right crushing machine according to your own situation.

获取价格